KANBAN

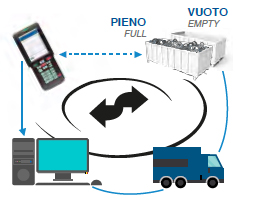

Kanban (literally signboard or billboard in Japanese) is a scheduling system for lean manufacturing and just-in-time manufacturing.

The consumption of the material is recorded and automatically communicated thanks to a special label with bar code suitable for optical reading placed on the storage box used in the warehouse and for each item used on production line. Then the item will be replenished with the quantities and the times defined in the contract. This inventory control system let to control the supply chain and to improve manufacturing efficiency.

(Datalogic memor)

The Consignment Stock is a stock management technique. The Supplier sends the goods at the Customer's warehouse while the property of the goods remain of the Supplier until the Customer pick-up the goods.

Only with the pick-up of the quantities needed and only at this time and for the amount taken, the ownership of the goods passes from the supplier to the customer. Then the supplier issue the invoice.

ADAVANCED LOGISITC SERVICES THAT WE CAN OFFER TO OUR CUSTOMER

Kanban (literally signboard or billboard in Japanese) is a scheduling system for lean manufacturing and just-in-time manufacturing.

The consumption of the material is recorded and automatically communicated thanks to a special label with bar code suitable for optical reading placed on the storage box used in the warehouse and for each item used on production line. Then the item will be replenished with the quantities and the times defined in the contract. This inventory control system let to control the supply chain and to improve manufacturing efficiency.

|

CUSTOMER BENEFITS

- cost reduction

- inventory resizing

- increasing productivity

- cancellation of the suppliers’ orders management

- the material is always ready for use

|

FAST_BATCH:

(Datalogic memor)

|

CONSIGNMENT STOCK:

The Consignment Stock is a stock management technique. The Supplier sends the goods at the Customer's warehouse while the property of the goods remain of the Supplier until the Customer pick-up the goods.

Only with the pick-up of the quantities needed and only at this time and for the amount taken, the ownership of the goods passes from the supplier to the customer. Then the supplier issue the invoice.

CUSTOMER BENEFITS

- Management and Financial Costs Reduction: stocks are not owned by the Customer until Customer pick-up

- No Lead-Time: the goods are always available and ready for their use